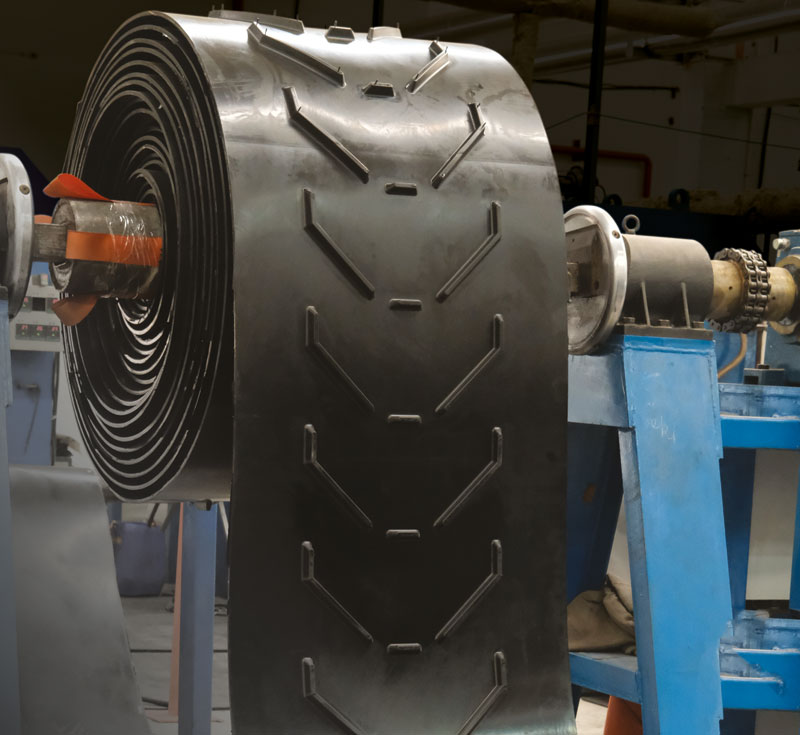

Finding The Best

Construction Services

We denounce with righteous indignation and dislike men who we are to beguiled demoralized by the charms of pleasures that moment, so we blinded desires, that they indignations.

Conatct Us

-

54B, Tailstoi Town 5238 MT,

La city, IA 522364 -

Working Hrs : 9.30am to 6.30pm